Low superheat high suction pressure – Low superheat and high suction pressure are common issues in refrigeration systems, leading to reduced efficiency, increased energy consumption, and premature compressor failure. Understanding the causes, impacts, and troubleshooting methods is crucial for maintaining optimal system performance.

This article delves into the intricacies of low superheat and high suction pressure, providing a comprehensive overview of the topic.

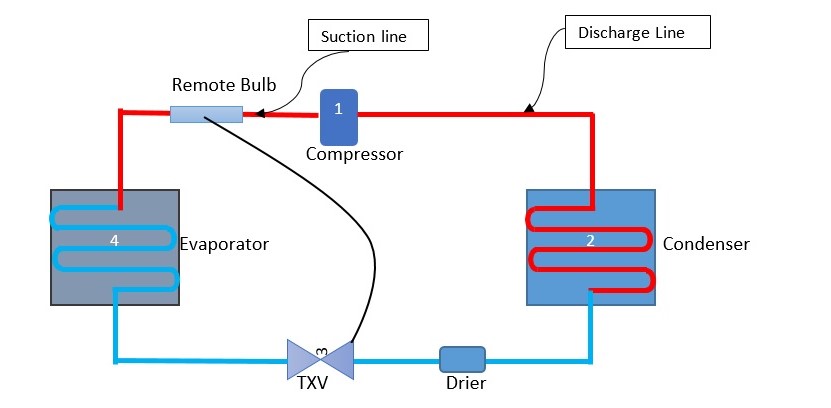

Causes of Low Superheat and High Suction Pressure

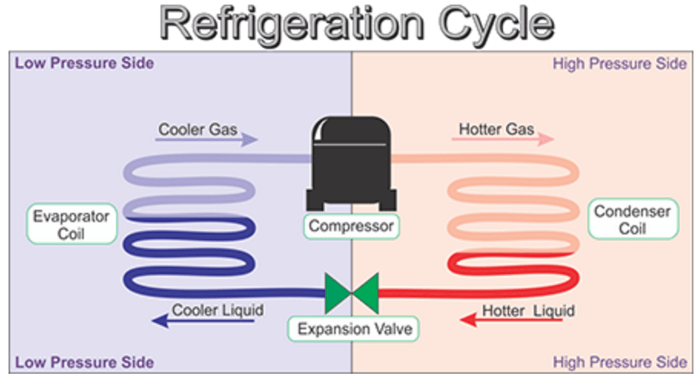

Low superheat and high suction pressure in a refrigeration system indicate underlying issues that need to be addressed to ensure efficient system operation and prevent potential damage. Various factors can contribute to these conditions, ranging from refrigerant leaks to dirty condenser coils and clogged capillary tubes.

Potential Causes

The table below Artikels some of the potential causes, their associated symptoms, and possible solutions:

| Cause | Symptoms | Potential Solutions |

|---|---|---|

| Refrigerant leak | Low refrigerant levels, reduced cooling capacity, visible leaks | Locate and repair the leak, recharge the system with refrigerant |

| Dirty condenser coils | Restricted airflow, increased head pressure, reduced heat transfer | Clean the condenser coils, remove any debris or blockages |

| Clogged capillary tube | Restricted refrigerant flow, reduced superheat, high suction pressure | Replace the capillary tube, check for any blockages or restrictions |

Impact on System Performance

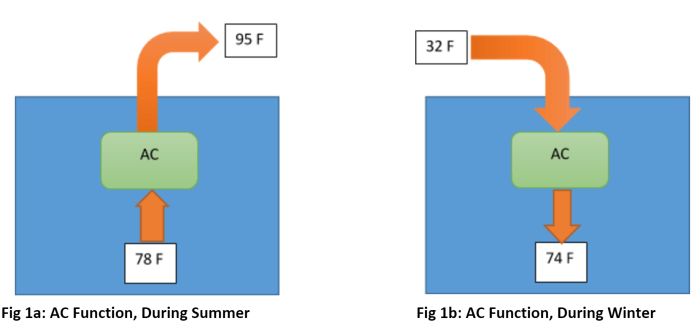

Low superheat and high suction pressure can significantly impair the performance of a refrigeration system. These conditions can lead to reduced system efficiency, diminished cooling capacity, and premature compressor failure.

Increased Energy Consumption

When superheat is low, the refrigerant enters the compressor as a wet vapor, which reduces the compressor’s volumetric efficiency. This, in turn, increases the energy consumption required to achieve the desired cooling effect.

Reduced Cooling Capacity

Low superheat also reduces the cooling capacity of the system. This is because the refrigerant entering the evaporator has a lower enthalpy, which limits its ability to absorb heat from the conditioned space.

Premature Compressor Failure

High suction pressure can put excessive stress on the compressor, leading to premature failure. This is because the compressor must work harder to overcome the increased pressure, which can cause overheating and damage to its components.

Troubleshooting and Repair Methods

Troubleshooting low superheat and high suction pressure issues involves a systematic approach to identify the underlying causes and implement appropriate repair methods. The following steps provide a comprehensive guide for technicians and homeowners to diagnose and resolve these issues effectively.

Step-by-Step Troubleshooting Process

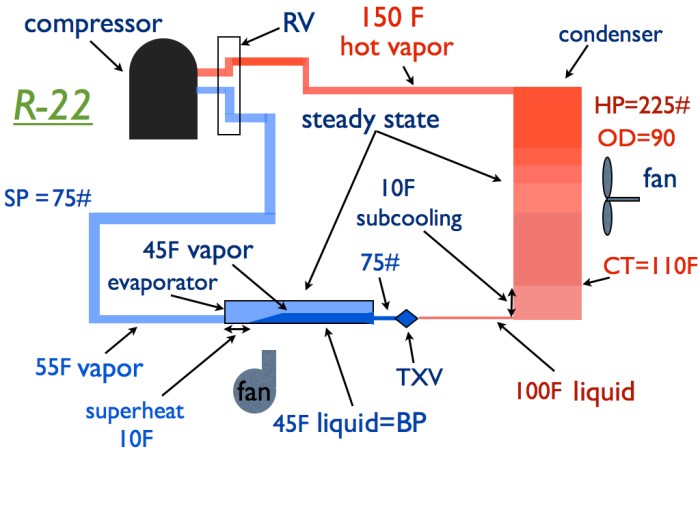

- Check Refrigerant Levels:Low refrigerant levels can result in reduced heat transfer and higher suction pressure. Using a refrigerant gauge, check the system’s refrigerant charge and compare it to the manufacturer’s specifications. If the levels are low, recharge the system according to the manufacturer’s instructions.

- Clean Coils:Dirty coils can restrict airflow, leading to lower superheat and higher suction pressure. Inspect the evaporator and condenser coils for dirt, dust, or debris. Clean the coils using a coil cleaner and a soft brush to remove any blockages.

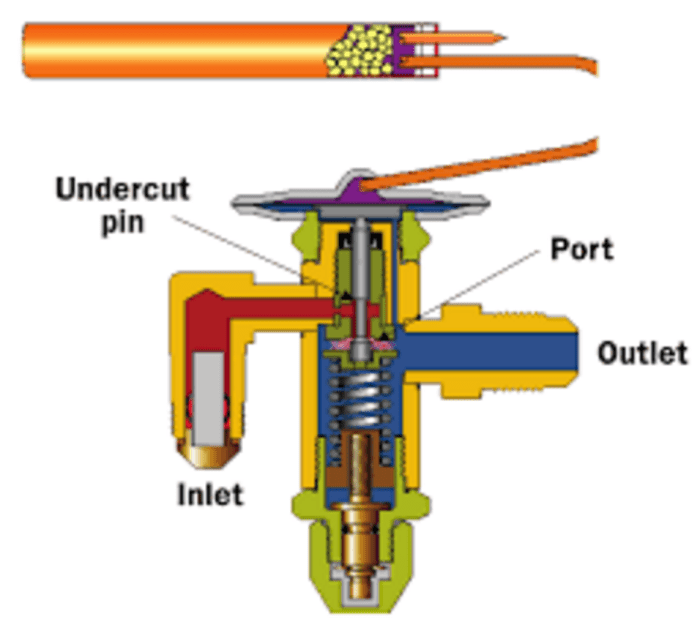

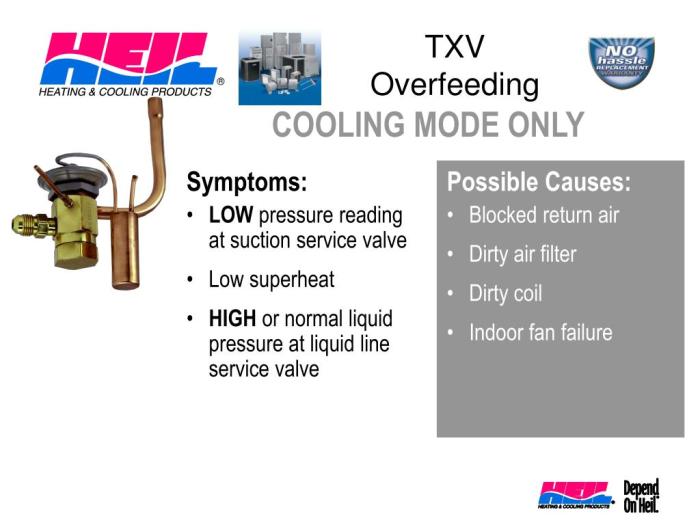

- Inspect Expansion Valve:A faulty expansion valve can cause refrigerant flow issues, resulting in low superheat and high suction pressure. Check the expansion valve for proper operation and replace it if necessary.

- Examine Compressor:A malfunctioning compressor can reduce refrigerant flow and increase suction pressure. Listen for any unusual noises or vibrations from the compressor. Check the compressor’s electrical connections and test its performance using a multimeter.

- Inspect Capillary Tube:A blocked or restricted capillary tube can cause refrigerant flow issues. Check the capillary tube for any kinks or blockages. If necessary, replace the capillary tube.

Troubleshooting Flowchart

The following flowchart illustrates the troubleshooting process and potential solutions for low superheat and high suction pressure issues:

- Start

- Check refrigerant levels

- If low, recharge system

- Clean coils

- Inspect expansion valve

- If faulty, replace

- Examine compressor

- If malfunctioning, replace

- Inspect capillary tube

- If blocked, replace

- End

Preventive Maintenance and Best Practices

Implementing proactive preventive maintenance strategies is crucial to prevent issues related to low superheat and high suction pressure. These strategies involve regular inspections, cleaning schedules, and refrigerant monitoring.

Maintenance Tasks and Benefits, Low superheat high suction pressure

| Maintenance Task | Benefits |

|---|---|

| Regular Inspections |

|

| Scheduled Cleaning |

|

| Refrigerant Monitoring |

|

Popular Questions: Low Superheat High Suction Pressure

What are the common causes of low superheat and high suction pressure?

Common causes include refrigerant leaks, dirty condenser coils, clogged capillary tubes, and overcharged systems.

What are the consequences of low superheat and high suction pressure?

Consequences include reduced cooling capacity, increased energy consumption, premature compressor failure, and system instability.

How can I troubleshoot low superheat and high suction pressure issues?

Troubleshooting involves checking refrigerant levels, cleaning coils, inspecting components, and analyzing system pressures and temperatures.